TeachBot

Skills Demonstrated

Working under the direction of Professor Harry Asada at MIT, I designed, developed, tested, and deployed a robotic workforce training solution for collaborative manufacturing.

Motivation

By 2025, Deloitte and The Manufacturing Institute estimates nearly 3.5 million manufacturing jobs will be needed in the US, but only 1.5 million are expected to be filled. The remaining 2 million jobs will likely not be realized due to a lack of skilled workers trained to work with robots. Despite this dearth in skilled labor, the International Federation of Robotics found that growth in automated manufacturing industries is accelerating. Other countries, particularly those in Europe, fill the gap between labor supply and demand with robust apprenticeship programs that the US notoriously lacks, and this leads domestic manufacturers to outsource system integration to consulting firms. This is both costly and short-term: if the manufacturer needs to tweak or repair the already-integrated automated system, all of the knowledge necessary to do so is external to the organization, so the manufacturer must pay the consultants again to return and modify the system. This absurd process leads us to ask, "Why can't manufacturing workers themselves be trained to perform system integration tasks?"

Customer interviews with small- and medium-sized manufacturing firms were extremely helpful. I discovered that an important, intuitive understanding is missing that would enable workers to design and improve manufacturing processes. A solution to this problem must:

- Teach workers necessary skills like feedback control,

- Enable workers to perform real tasks like pick-and-place operations,

- Make learners feel engaged, and

- Be priced appropriately for the (generally smaller) manufacturers who need skilled workers.

Solution

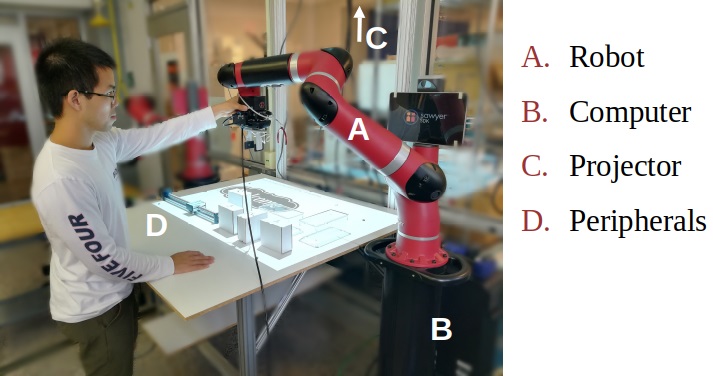

After doing a careful analysis of existing products and diving deep into the relevant teaching science literature, we designed a fully autonomous robotic instructor to teach workers on a manufacturing line how to use robots effectively. Our system consists of a collaborative robot system (e.g. RethinkRobotics Sawyer, Universal Robot, ABB Yumi, etc.), a computer with an internet connection, a projector to display educational graphics, and peripheral devices like conveyor belts and CNC equipment to simulate a real manufacturing environment.

A previously-thought-of-as-critical piece of hardware is missing from our bill of materials: a human instructor. The robot serves as both teacher and demonstration machine, leveraging its existence as a robotic system to teach robotics more effectively. Rather than exclusively relying on diagrams and lectures to illustrate concepts like playback control and waypoints, TeachBot guides learners to interact with a physical embodiment of the concepts about which they are learning. As we demonstrate, TeachBot's "learning by touching" curriculum is superior to more traditional teaching methods.

Evaluation

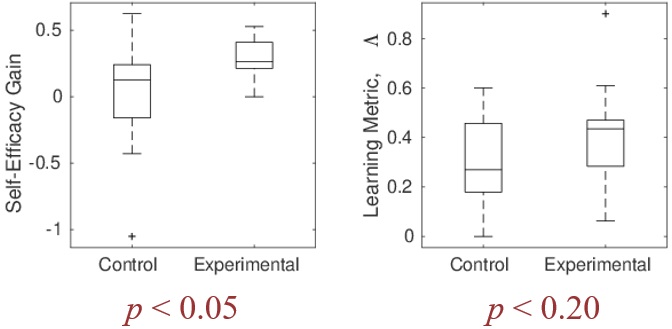

To evaluate our solution, we leveraged our relationships with our industry sponsors to collect human subjects for randomized control trials. Subjects were divided randomly into two groups: (1) a control group that watched a traditional video lecture and (2) an experimental group that took the TeachBot learning module. Both groups were given a pre- and post-test to evaluate how much they learned and how each learning method affected their self-efficacy regarding robotics.

Our results demonstrate that people learn significantly more from TeachBot than they do from traditional video lectures. Furthermore, TeachBot helps learners feel more confident working alongside a robot.

Moving Forward

The results I've seen are extremely promising. My favorite anecdote from administering human subject tests is watching learners who have never interacted with a robot before evolve from fear and skepticism, observing the TeachBot from several yards away, into excitedly curious and confident explorers, playing with TeachBot's arm, and exclaiming "Oh!" as they discover for themselves how a robot could help them do their jobs.

TeachBot won several awards, including the National Science Foundation Innovation Corps Teams and Fusion grants, First Place at the MIT Mechanical Engineering Research Exhibition, and millions of dollars in grant money from the Advanced Robotics for Manufacturing Institute and others. A prominent Boston start-up incubator offered TeachBot $500,000 in seed funding.

We successfully deployed prototypes of the TeachBot system to small and medium-sized manufacturers and community colleges in the state of Massachusetts. Today, TeachBot is being used to train the future manufacturing workers of America.

To learn more about the project, read our paper and download our award-winning poster. All of our software is open source on GitHub.